Vacuum conveying and its great benefits

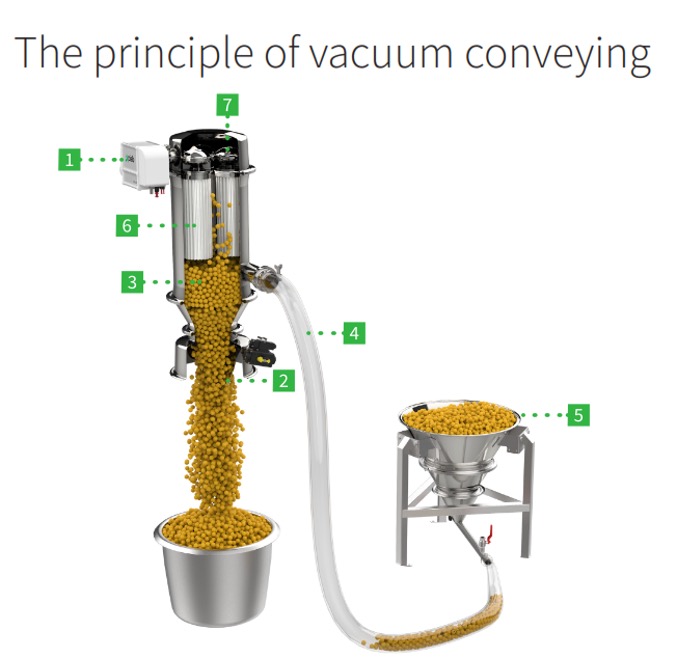

Vacuum conveying is a modern way of transporting powders and granules with a number of benefits.

Reduce product scrap and product contamination

Small Footprint

Minimize maintenance

Dust free working environment

Production flexibility

Products

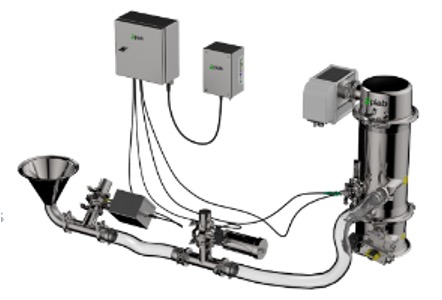

Piab’s product series is called piFLOW and it is offered in five models for the food industry:

the piFLOW for the basic food industry.

piFLOWp for premium applications>

piFLOW t for conveying tablets, capsules or other fragile material that needs gentle conveying.

piFLOW fc for food/chemical applications without acid resist demands.

All vacuum conveyors have a 5 year warranty.